Menu

Technology of Mixing

Sardik is your technology partner. You define the problem, we design a solution.We aim for your objectives all while providing additional value in the form of additional energy savings,increased throughput,reduced waste,or improved output quality.

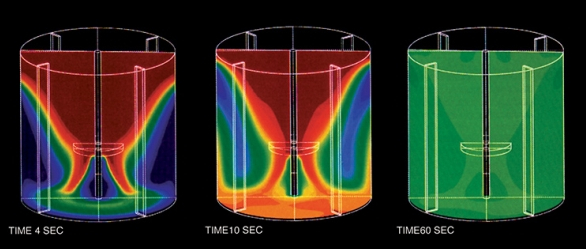

C.F.D. is a powerful fluid flow analysis engineering software tool which simulates many types of mixing applications including blending, solids distribution, gas-liquid dispersion, heat transfer and liquid-liquid dispersions.

It can be used to predict operating parameters such as fluid velocities, flow patterns, blend times, gas hold-up, temperatures, pressures, power draw, shear and strain rates and many other criteria.

With the ability to predict mixing performance, optimum impeller/tank/baffle selection and configuration can be made leading to more efficient mixing systems, better process control, higher yields, higher selectivity, etc. C.F.D. also allows more accurate mixer scale-up, and can be used to improve the performance of existing equipment.

By developing a link between the output from our mixer selection software package (Mixing Assist) to the C.F.D. software with automated grid generation of impellers, tanks and baffles, C.F.D. results are easily and quickly processed. This capability is in the hands of every Hayward Gordon sales engineer, allowing our customers regular access to this very useful tool. Advanced post-processing ensures the best possible viewing tools to interpret the results.

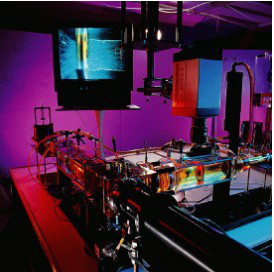

Digital Particle Image Velocimetry (DPIV)

DPIV helps our engineers to better understand the flow phenomena occurring in mixing tanks. An Argon-Ion laser light sheet illuminates fluorescent, neutrally buoyant particles. A CCD camera captures the images, then an advanced timing system and a computer with image board freezes and digitizes the images. The picture below shows the motion of fluorescent particles illuminated by a sheet of Argon-Ion laser light. The particles (60 micrometers) are small and neutrally buoyant, so they follow the liquid flow. The tank is equipped with a pitched-blade turbine. The particle motion is filmed with a CCD camera. The velocity field is then extracted from the digitized images using cross-correlation software. Armed with this information, our engineers can better design agitation equipment for your specific application.

DPIV technology has the capability of measuring the entire fluid velocity field in a tank almost instantaneously making it possible to study large-scale, time-dependent phenomena in the tank, which is responsible for much of the mixing process.

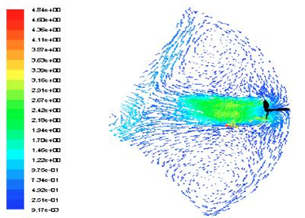

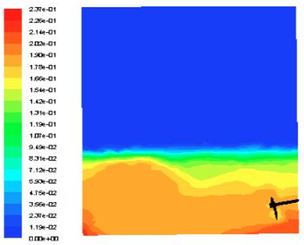

The image below shows the result of a series of full flow field measurements using DPIV. The color shows the local, time-averaged velocity. Fast-moving regions are colored red and slow-moving regions are colored blue. The pitched-blade turbine creates a mixed axial/radial flow pattern. The highest velocities are found at the impeller blade tip. The velocities at the liquid surface are an order of magnitude lower.

When used in conjunction with Computational Fluid Dynamics (C.F.D), DPIV provides the most accurate application evaluation possible. Various mathematical models used by the C.F.D software must be validated to ensure the accuracy of the procedural results. DPIV analysis provides that validation with actual experimental data and, if necessary, DPIV test data can be used to further improve C.F.D models so the predictions have an even higher degree of accuracy.

Scale-Up Your Process

Proper scale-up technology is a key factor in reliability. And successful scale-up requires the knowledge and experience that Sardik has in process mixing operations, fluid mixing, and obtaining accurate data on a specific operation.

We offer scale-down/scale-up test services. We test power and torque levels as well as impeller designs and geometric ratios to achieve the optimal solution for your requirements. We can simulate your exact basin and/or vessels so that our test will work the same way as your plant - guaranteed!

Our torque-based scale-up technology is at the heart of our ability to solve customer problems and guarantee full-scale success through laboratory tests.

We use a 3-step approach:

●Scale-down speed to simulate the problem

●Find the solution

●Scale-up the solution

●Scale-down speed to simulate the problem

●Find the solution

●Scale-up the solution