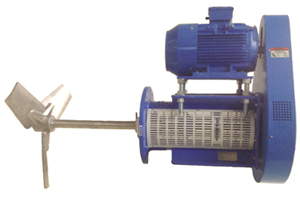

Though this type is compact and lightweight, it can perform partially strong agitation as it can be mounted in the chosen position.

By mounting the mixer on the tank in an off-set position, the need for baffle plates can be eliminated without affecting the steady flow of liquid.

Sardik has provided agitators for every service imaginable, from lab scale to the largest mixers in the world. Sardik can meet your needs for any application, from batch blending to continuous solids suspension to mass transfer applications. Experience, expertise, and cutting edge technology allow Sardik to provide the optimal mixing system to suit any need.

The mixers impeller makes up half of a complete mixing system. With an unparalleled commitment to innovation, Sardik optimizes the impeller selection and sizing to provide the most effective and efficient mixing for every installation. Sardik offers a wide range of sizes and designs of mixer impellers to meet any mixing need.

Sardik V-belts drive mixers the following advantages are considered:

Hydrofoil impellers

Energy efficient hydrofoil impellers are furnished standard, with other distinct designs from Sardiks hydrofoil family of impellers available as an option. This exclusive family of hydrofoil blade" impeller was developed through extensive testing and consultation with aerospace engineers to maximize pumping efficiency. Each impeller is designed specifically for the application by calculating the fluid velocity over the turbine blades to determine the blade curvature that will be the most efficient. The result is more flow for less power. Unlike cast impeller blades that may break or cause balance problems, hydrofoil impellers are fabricated from plate steel, fixture welded and pitched for vibration- free operation. On larger impellers, the blades are welded to Sardiks unique casting impeller hub, allowing easy installation without running the risk of a removable blade being installed improperly or slipping out of pitch. The casting hub also guarantees easy disassembly from the shaft in the future years, when so many other hubs may be stuck in place and would have to be removed with a cuffing torch.

Tapered roller bearings bearing unit

Premium Timken Type E Tapered Roller Bearing Housed Unit Selection, piloted dual tapered-roller bearings provide higher radial and thrust carrying capacities for longer trouble-free life. These quality bearings are stocked nationwide and come complete with their own piloted housings and integral lip seals. The bearings simply bolt in place on the mixer. The same size bearing is used front and rear to reduce spare parts requirements.

The Sardik V-Belt drive is designed for easy maintenance and long life, with a minimum 1.5 service factor on all models. Standard 5V, SPA or SPB sheaves are used complete with premium "QD" or “TB” style bushings for a more dependable drive that is easier to maintain.

Mixers shafts

Oversized shafting is used on all Sardik mixers, precision machined for vibration-free operation.Wear sleeves, Chrome, aluminum oxide or chrome-nickel-boron flamespray hardening at the seal is optional to extend the life of the shaft on mixers with stuffing glands, where abrasive products may accelerate wear (not necessary with mechanical seals).

Housings

The Sardik side entry mixers housings are designed to be the strongest available, fabricated from steel and oversize for easy maintenance and durability.The housing is precision line bored for perfect alignment and quality. We learned from experience that hinged motor mounts tend to work loose and rattle over time, so Sardiks motor mount is designed for simple adjustment using four oversize studs to tighten the belts.

Guards

The Sardik V-Belt guards are built with ample clearance and ventilation for belt cooling, and to allow changes in ratio if required. All Sardik guards are fabricated from steel for durability. Plastic guards may be cheaper to build, but ultraviolet rays and temperature extremes degrade plastics allowing them to break over time.

Mechanical seal

Sardik Mixers offers seals to meet every requirement. The traditional packed gland is available in many configurations and can be supplied with flushing fittings or force fed lubricators. Mechanical seals in single, double and split designs are also available for positive leak-free operation, including the seal preferred at your plant.

Maintenance

The primary goal when developing the Sardik side entry mixers line was to make them easy to maintain. All access areas are large and open for servicing. The grease fittings for the bearings and lube ports for the seals are reached from one obvious location. All seal parts, shaft bearings and belt drive components on the mixer are replaceable without removing the mixer or draining the tank. Shaft retraction (to shut off tank leakage) is the simplest in the industry, by loosening one bearing and tightening two jacking screws, all located in plain sight and easily accessible. Tank shut-off for repacking the stuffing gland can be done without disturbing the belt drive. To service mixer bearings, a collar is supplied to hold the shaft in position during bearing removal. Assembly points include jacking screws to make disassembly an easy task even after years of demanding service.